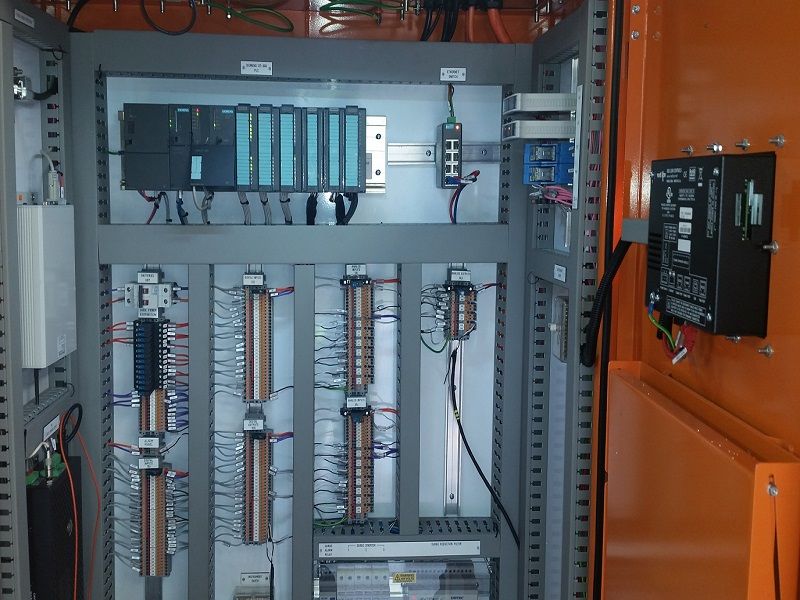

Siemens S7 300 PLC with DNP3 Communications

-

Old MD1000 alongside new S7-300 switchboard

-

Legacy MITS MD1000 RTU installed nearly 20 years ago!

-

New Siemens S7-300 with TIM4-RE DNP3 Communications card

MITS MD1000 RTU Replacement

Background:

Queensland Urban Utilities had an ageing fleet of Logica MD1000 RTU's installed some 20 years ago which had reached the end of their service life. QUU decided to replace the ageing fleet with their standard Siemens S7-300 PLC range with the new DNP3 communications card.

Preliminary Works:

10 sites were selected for a trial, and to form the basis of new standard PLC code for rollour to future installations. The old MD1000 IsaGraf code was investigated, and a standard I/O list to cater for all site I/O combinations was created. A new Reservoir functional spec was developed in conjunction with Witthoft Engineering and QUU staff during numerous stakeholder workshops. From this new functional specification a completely new Siemens PLC program, Redlion HMI and Mosaic SCADA was developed with standard code able to take into consideration numerous site options such as:

- Up to 2 Reservoirs onsite (Level gauges/electrodes

- Suction and Delivery Flowmeters

- Inlet and Outlet Valves

- Chemical Dosing

- Mixers

The standard code handles all these options, with site specific configuration code enabling or disabling optional equipment as required.

Control System:

A full testbed was setup at Wagtec premises, with all new code put through its paces. Testing with the Mosaic SCADA system was done at QUU headquaters where a full testbed connected via Telemetry was used to perform point-2-point testing

Cutover:

The Reservoir switchboards were changed out in conjunction with J&P Richardson electricians. Site setpoints were copied over from the old MD1000 to the new Siemens S7, and all functionality tested onsite back to the control room SCADA. In total it took around 8hrs per site to physically changeout the switchboards and perform a number of standard tests to ensure correct reservoir operation.

+61 418 152 053

+61 418 152 053